|

|

|

|

|

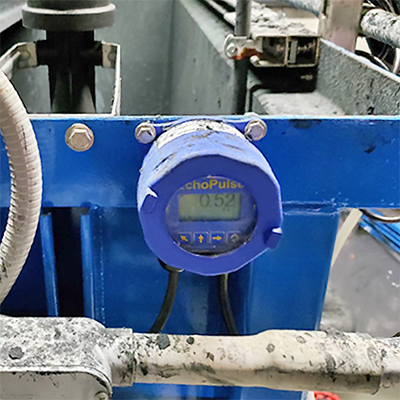

When an Arkansas tannery needed reliable level measurement of their pre-treatment tanks, they turned to Flowline. Tannery effluent is filled with organic material and suspended solids that must be screened and removed prior to treatment. The resulting wastewater pours into a collection tank with the consistency of watery cake batter. Laden with chromium salts, a primary tanning chemical, the media is coating, corrosive and sometimes foaming. Plant operators complained that past guided wave level sensors only lasted a year due to corrosion, and ultrasonic level sensors became intermittent whenever surface foam developed. For these reasons, Flowline suggested the use of our non-contact radar sensors that are unaffected by the surface characteristics of the liquid. The radar sensors provide continuous level data to the tank indicator and PLC, which controls the waste screening and transfer. Flowline is reliable level measurement. |