|

|

|

|

|

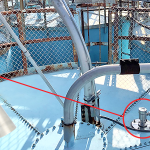

When a Midwest university needed reliable level measurement of their boiler tanks, they turned to Flowline. The boilers heat, pump and recirculate hot water throughout the basketball stadium, team locker rooms and training facility. The boilers were initially installed with a metal high & low level float switch mounted in the external standpipe. The switches failed every two years due to scaling or corrosion and required replacement. The issue then became lead time which averaged six weeks. Fed up, the maintenance manager said, “That’s an eternity. We need a reliable, corrosion resistant level sensor that mounts in a standpipe and is unaffected by scaling. Additionally, we want to display the gallons and set alarms.” For these reasons, Flowline suggested our guided wave sensor and level controller. The guided wave sensor provides reliable level data to the indicator, which actuates the alarms and repeats the 4-20 mA signal to the building management system. Flowline is reliable level measurement. |