|

|

|

|

|

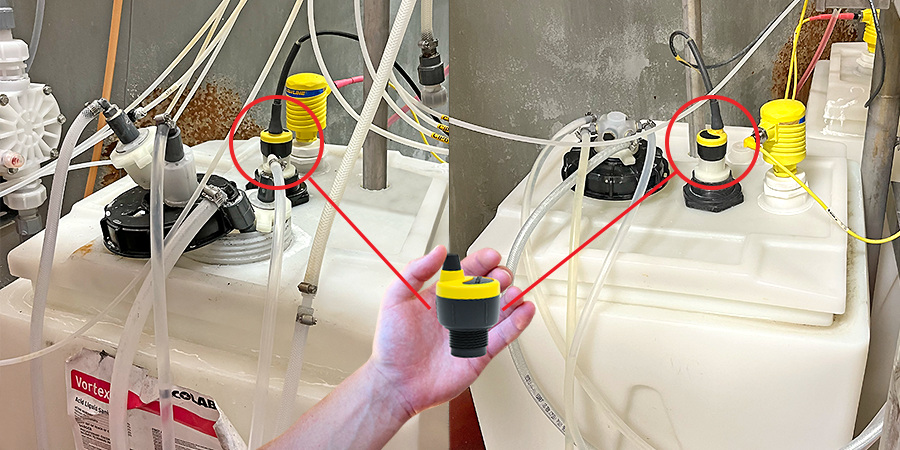

When a Wisconsin dairy bottler needed reliable level measurement of their IBC chemical tanks, they turned to Flowline. The dairy utilizes an acetic and octanoic acid organic disinfectant that foams when injected into or on their process equipment. The IBC’s supply the CIP chemicals to their spray systems and each tote is automatically filled from bulk storage. There the engineer had ongoing float level sensor failures due to corrosion and wanted a belt and suspenders level solution. For this reason, Flowline suggested our non-contact ultrasonic sensors for measurement with an adjustable PP Smart Trak for high and low-level alarms. The ultrasonic sensors provide reliable level data to the PLC which controls the IBC refill process. Flowline is reliable level measurement. |