|

|

|

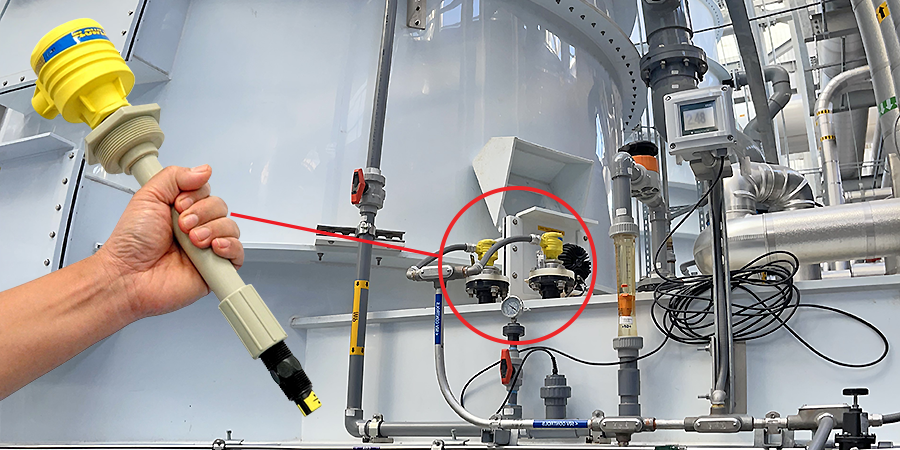

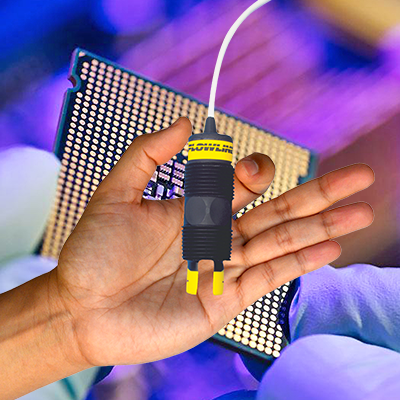

When a Gulf Coast semiconductor producer needed reliable level detection of their scrubber sumps, they turned to Flowline. Chemicals like silane, phosphine and arsine are used in wafer fabrication, and the resulting hazardous vapor stream must be scrubbed to EPA standards prior to release. The abatement process is constant during manufacturing and managing the scrubber sump levels is critical. The integrator needed a reliable, corrosion resistant level switch that’s unaffected by residual particulates or chemicals. For this reason, Flowline suggested our Switch-Pak single-point ultrasonic level switch that’s ruggedly constructed of corrosion resistant PP. Two ultrasonic switches provide reliable level detection to the PLC, which controls each sump. Flowline is reliable level measurement. |