|

|

|

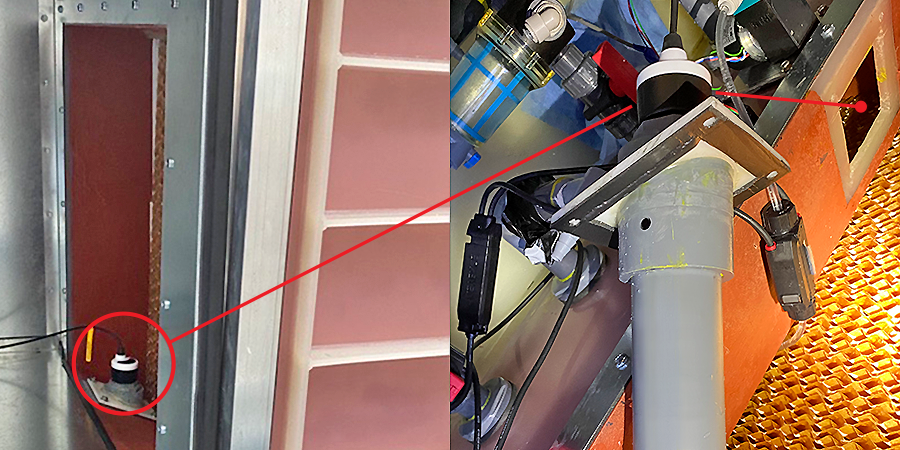

When a Midwest HVAC contractor needed reliable level measurement of their clients cooling tower sumps, they turned to Flowline. After numerous level failures, a hospital contracted with them to replace every float level sensor with something robust. Their engineer said that float failures are caused by scaling, corrosion and sump turbulence. In changing, he wanted level measurement versus switching, because it gave them set point flexibility in the PLC. For these reasons, Flowline suggested our non-contact and corrosion resistant ultrasonic sensors installed in a standpipe which dampens turbulence for a clean signal output. The ultrasonic sensors provide reliable level data to the PLC that actuates the fill valve. Flowline is reliable level measurement. |