|

|

|

|

|

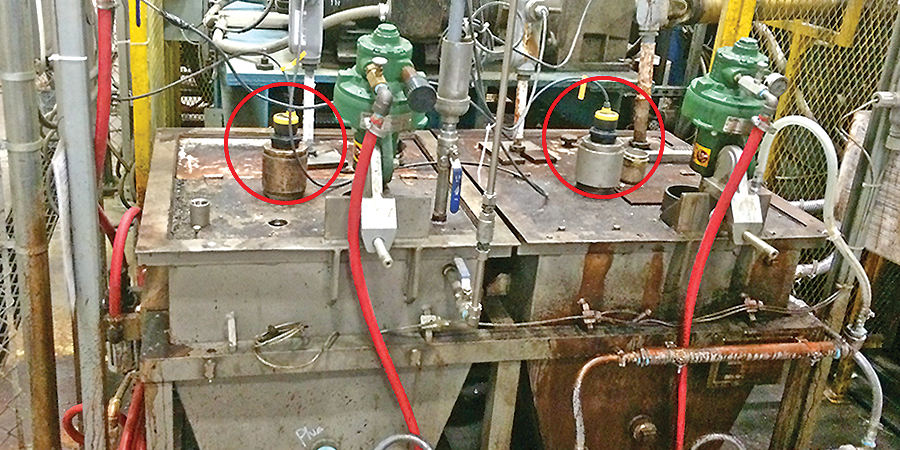

When a Utah manufacturer needed reliable level measurement of their batch mix tanks, they turned to Flowline. The company blends corrosive etching solutions and level height is used to determine the amount of each ingredient added to a batch. The solutions are mildly corrosive, somewhat viscous and they foam during mixing. The operators had experienced ongoing maintenance problems with their previous float level sensors due to material build-up. For this reason, Flowline suggested the use of our non-contact, ultrasonic liquid level sensors that are unaffected by corrosive or coating media. The sensors were installed in a stand-pipe to isolate the measurement from surface foam. Each ultrasonic sensor provides continuous level data to the PLC, which in turn, controls the batch, blending and dispensing process. Flowline is reliable level measurement. |