|

|

|

|

|

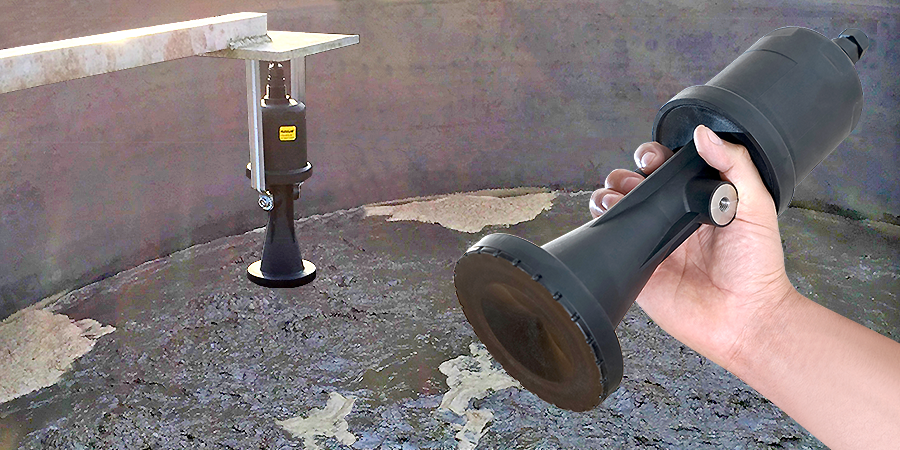

When an Idaho water treatment plant needed reliable level measurement of their clarifier tanks, they turned to Flowline. The operators add ferric chloride to wastewater in order to coagulate and separate the solids in their stage one clarifiers. During which, the highly corrosive iron-based chemical releases heat, vapor and foam when agitated. The plant experienced failures with pressure level sensors due to corrosion and clogging, and ultrasonic sensors due to foam and vapor. For this reason, Flowline suggested the use of our non-contact pulse radar level sensors that are unaffected by foam, vapor or agitation. The radar sensor provides continuous level data to the SCADA system, which in turn, monitors the clarifiers and controls the process. Flowline is reliable level measurement. |