|

|

|

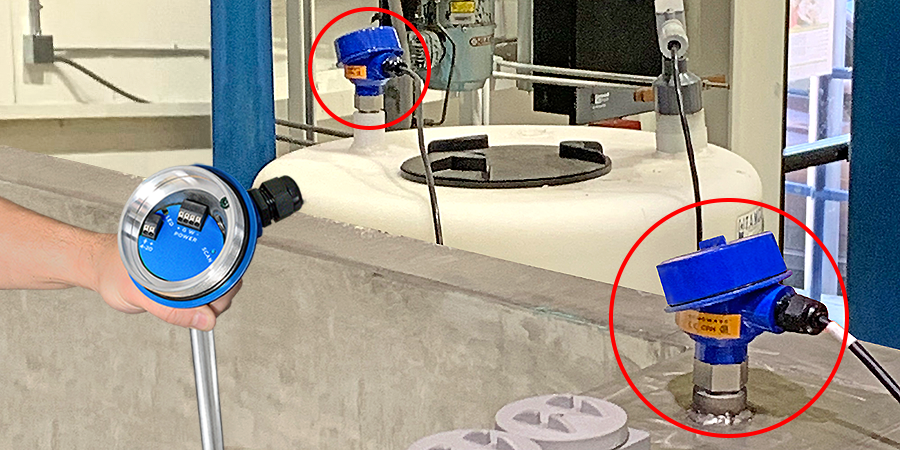

When a Canadian manufacturer of metal aircraft, satellite and military parts needed reliable level measurement of their chemical day tanks and parts cleaning baths, they turned to Flowline. Prior to metal finishing, the aluminum or titanium parts are soaked in baths to remove residual grease, oil and emulsions. The alkaline cleaning chemical foams when pumped to and from the day tanks, and into the baths. During which, plant engineers complained of intermittent measurement from past ultrasonic level sensors, due to acoustic signal attentuation. For this reason, Flowline suggested the use of our guided wave sensors that are unaffected by foaming chemicals and grease. The guided wave sensors provide continuous level data to the PLC which replenishes the day tanks and controls the bath process. Flowline is reliable level measurement. |