|

|

|

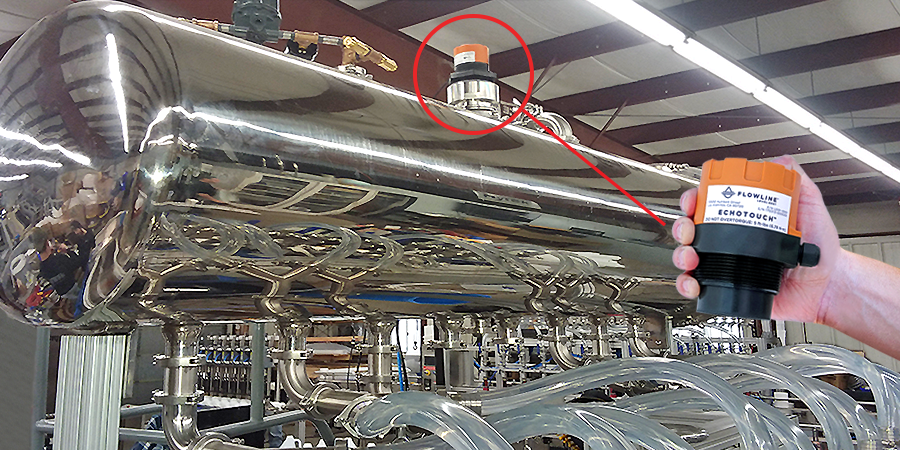

When a North Carolina equipment manufacturer needed reliable level measurement of their filling machine batch tank, they turned to Flowline. Their client bottles and distributes high purity chemicals to pharmaceutical research labs and universities. The batch tank receives, blends and dispenses chemicals into twenty one liter bottles per batch. Initial tests revealed that the originally specified ultrasonic level sensor became intermittent when condensation developed in the tank. For this reason, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensor provides reliable level data to the PLC which controls the batch make up and filling. Flowline is reliable level measurement. |