|

|

|

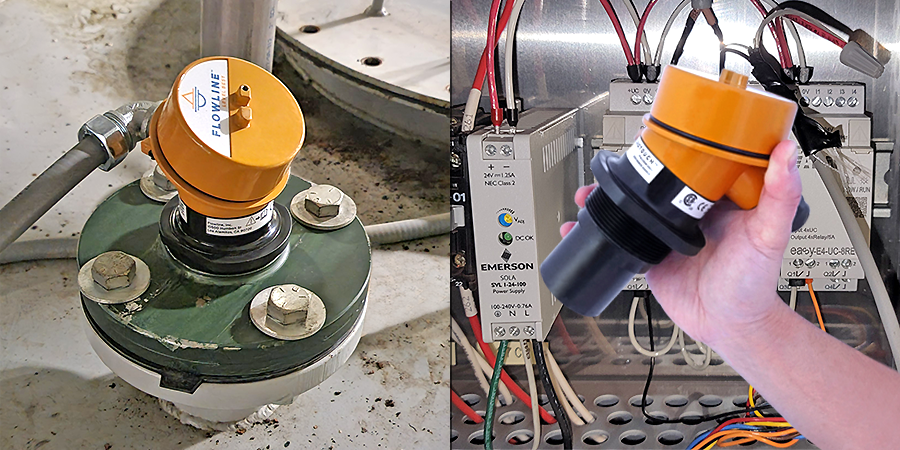

When a New Jersey pharmaceutical company needed reliable level measurement of their clean in place chemical waste tank, they turned to Flowline. Between production runs, the lines are shut down for cleaning, rinsing and sanitization. Depending on the line, the cleaning chemicals often include sodium hydroxide, nitric acid or hydrochloric acid. During rinse, the chemicals are sprayed off with ultrapure water that drains to a basement storage tank awaiting treatment. There the operator said that past pressure level sensors failed every six months due to corrosion attack and the room was a hazardous area. For these reasons, Flowline suggested our intrinsically safe, non-contact ultrasonic sensors with PVDF transducers that are ideal for corrosive media. The ultrasonic sensor provides reliable level data to the PLC, which monitors the tank and transfers the waste into treatment. Flowline is reliable level measurement. |