|

|

|

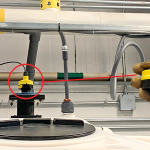

When a Midwest corrugated paper manufacturer needed reliable level measurement of their cooling tower water sumps, they turned to Flowline. The firm produces custom boxes, inserts and point of sale display packaging for beverage companies, and their processes generate substantial heat. Machine temperatures are regulated with cooling water supplied by two towers. There the facility operator experienced frequent float level switch failures due to corrosion, scaling or chatter, and replacement forced costly downtime. For these reasons, Flowline suggested our non-contact ultrasonic level sensor with four relays installed in a standpipe. The relay set points are configured to the previous float levels for seamless integration. The ultrasonic sensors provide reliable level switching to the PLC which controls the cooling process. Flowline is reliable level measurement. |