|

|

|

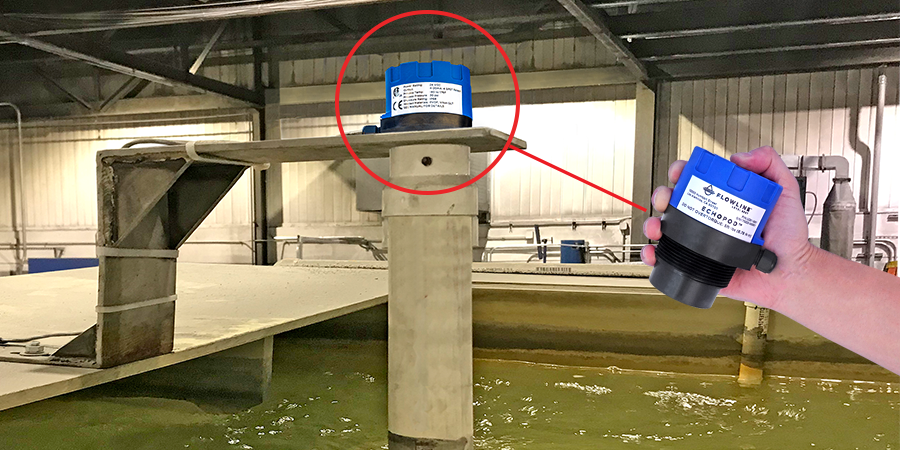

When an Ohio metal finishing company needed reliable level measurement of their electroplating baths, they turned to Flowline. The firm specializes in the chrome and nickel plating of automotive and motorcycle parts for aftermarket suppliers. They run six lines with twenty-four baths that degrease, etch, plate and rinse. The baths are hot, turbulent, foaming or corrosive, and evaporation is constant. The operator said that previous float, conductance and pressure level sensors failed within months, and they needed reliable level measurement. For these reasons, Flowline suggested our corrosion resistant, non-contact ultrasonic sensors installed in a standpipe to dampen turbulence and isolate the sensor from surface foam. The ultrasonic sensor provides reliable level data to the PLC, which monitors the baths and controls their refill. Flowline is reliable level measurement. |