|

|

|

|

|

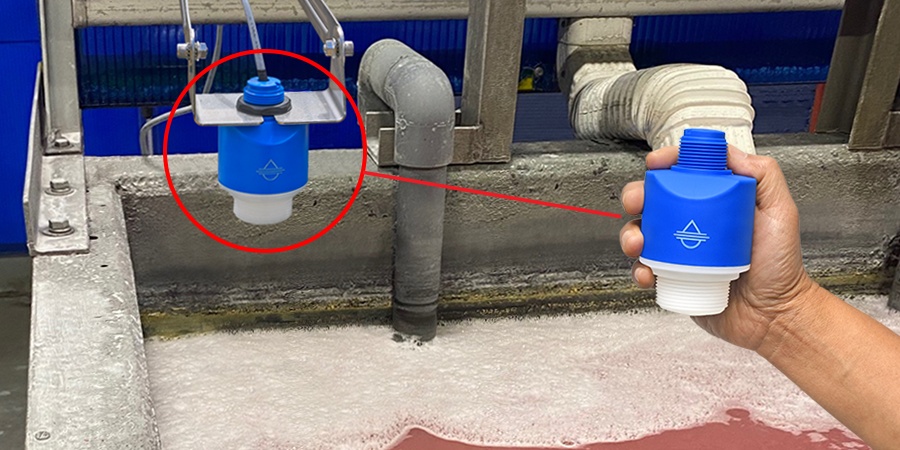

When a Midwest aerospace company needed reliable level measurement of their plating tank lines, they turned to Flowline. The firm produces metal housings for electronic systems and plates or coats those parts to customer requirements. In their first stage dip tanks, parts are etched with a blend of nitric acid, phosphoric acid and foaming surfactant to remove grease and particles. There the operator had ongoing problems with ultrasonic level sensors whose signal would attenuate every time foam developed in the tank. He said, “I want a non-contact, corrosion resistant level sensor that measures reliably, with or without surface foam.” For this reason, Flowline suggested our 80-GHz radar sensor that’s entirely constructed of PVDF and unaffected by plating foam or vapor. The radar sensor provide reliable level data to the PLC, which monitors the tanks and controls their refill or chemical feed. Flowline is reliable level measurement. |