|

|

|

|

|

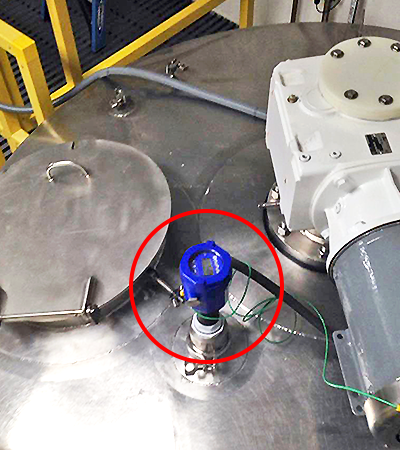

When a Midwest manufacturer of protein drinks needed reliable level measurement of their batch mix tanks, they turned to Flowline. The firm blends base liquid and powder supplements into custom nutritional products for professional and collegiate sports teams. The mixing process is level and time measured as operators manually fill each tank with batch ingredients. During which, the media surface is agitated in liquid or slurry form, and the air gap above the media is clouded with dusty powder. Requiring non-contact level measurement, the operator previously installed ultrasonic sensors. They worked fine until the powder and resulting dust attenuated their acoustic signal. For this reason, Flowline suggested the use of our radar sensors that measure through airborne powder. The radar sensor provides continuous level data to the PLC, which monitors the tank and controls the mixer. Flowline is reliable level measurement. |