|

|

|

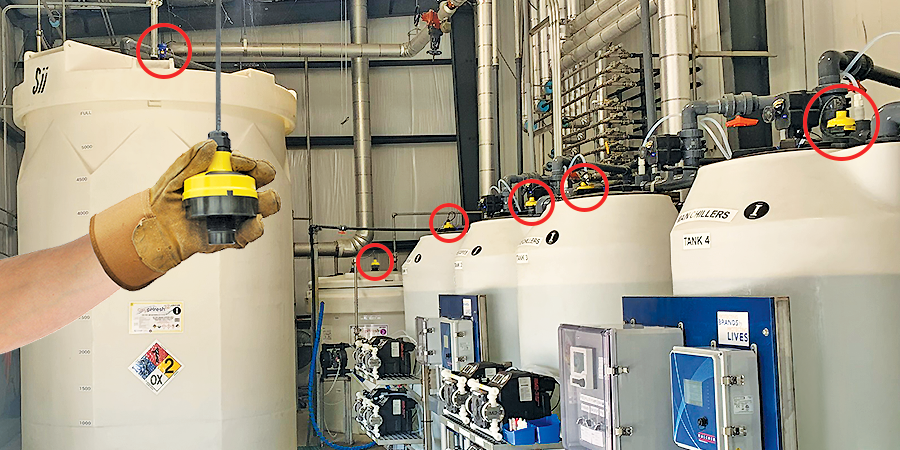

When an Iowa food processing company needed reliable level measurement of their chemical feed tanks, they turned to Flowline. Food safety is their highest priority and the use of sanitizing chemicals is central to maintaining both food and equipment cleanliness. The plant runs three shifts a day, two shifts processing and one shift cleaning. During which, a foaming solution of peroxyacetic acid is sprayed on, brushed and then power washed off the processing equipment. Meeting this demand, requires a highly reliable chemical storage, feed and inventory management system. Level driven, the system integrator wanted corrosion resistant, non-contact sensors. For these reasons, Flowline suggested our ultrasonic sensors for the day tanks and radar sensors for the vaporous storage tanks. The ultrasonic and radar sensors provide reliable level data to the PLC, which monitors all tanks and controls the feed process. Flowline is reliable level measurement. |