|

|

|

|

|

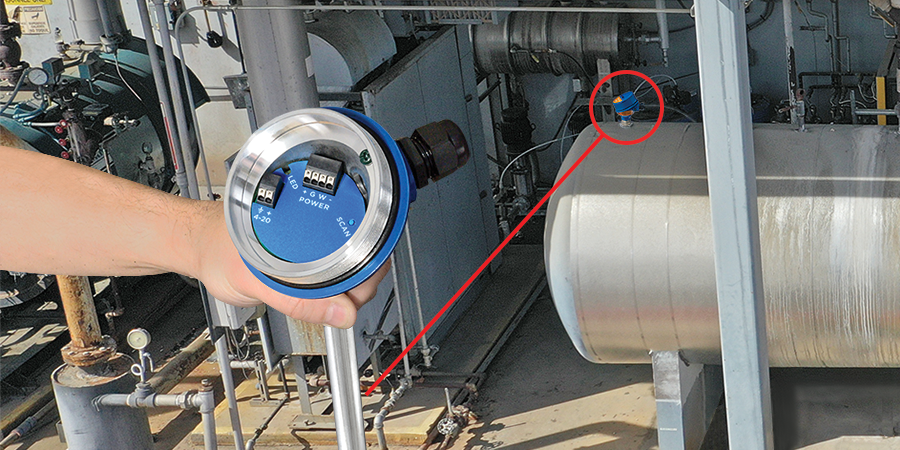

When a Northeast manufacturer of rubber products needed reliable level measurement of their boiler feed and condensate return tanks, they turned to Flowline. The company produces high pressure hoses that are used in truck and heavy equipment applications. Hoses are hand made on mandrels that roll layers of rubber, fabric, wire and tape to their clients specification. At various production stages, hot water and pressure is applied to cure, release or test the parts. The spent hot water and condensate is then collected and pumped back to the feed tank for recirculation to the boiler. There the operators complained that previous float level switches often failed due to scaling or corrosion. For this reason, Flowline suggested our guided wave sensors that are unaffected by scaling and feature rugged stainless steel antennas. The guided wave sensors provide reliable level data to the PLC, which monitors the feed tanks and supplies the boilers. Flowline is reliable level measurement. |