|

|

|

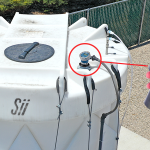

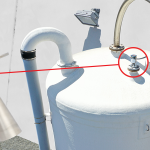

When a Midwest water treatment plant needed reliable level measurement of their new sodium hydroxide storage tank, they turned to Flowline. The city transitioned their main water supply to a different lake and installed a pump booster station to transport the water 3.5 miles to the plant. At the station, they begin the water treatment process by steadily injecting sodium hydroxide. As caustic is corrosive and highly coating, the plant operator wanted reliable non-contact level measurement with a local display and alarms for the chemical truck driver to monitor during tank refill. For this reason, Burns & McDonnell specified our reflective ultrasonic level sensor, level controller and NEMA enclosure with alarm indicators. The ultrasonic sensor provides reliable level data to the SCADA system and local display. Flowline is reliable level measurement. |