|

|

|

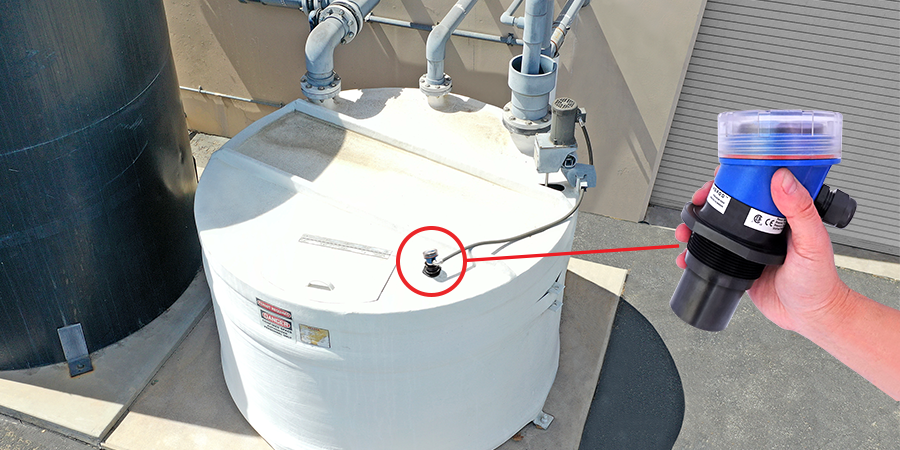

When a Wisconsin metal auto parts manufacturer needed reliable level measurement of their rinse water neutralization tank, they turned to Flowline. Parts are pressure washed with solvent to remove oil, grease and contaminants. Then they’re rinsed in a heated water tank with 2% hydrochloric acid. Each day, the rinse tank is emptied, filtered and pumped to a neutralization tank for reclamation. There the operator complained that a different ultrasonic level sensor brand became unstable shortly after transfer of the heated water due to condensation on the transducer. For this reason, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation. See how. The ultrasonic sensor provides reliable level data to the PLC which controls the process. Flowline is reliable level measurement. |