|

|

|

|

|

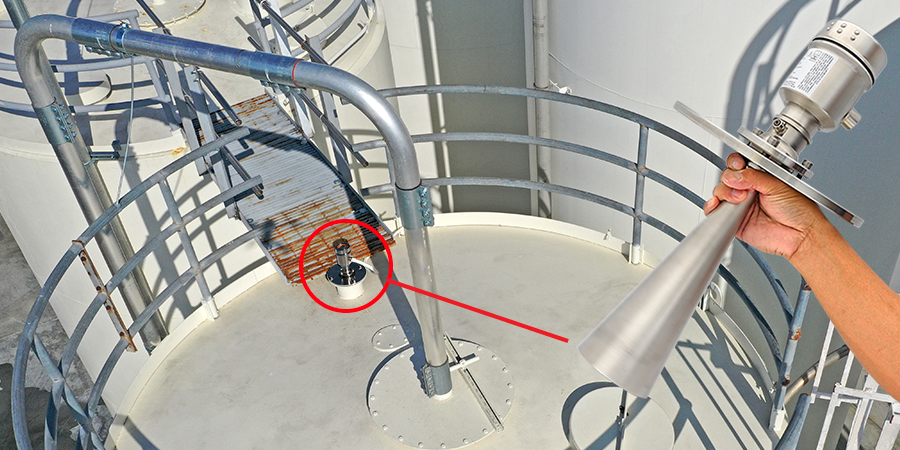

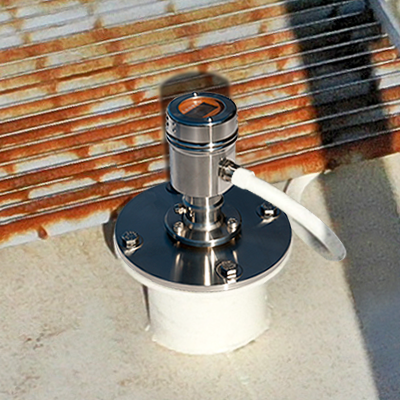

When a Midwest manufacturer of plastic bottles and packaging for cosmetic, pharmaceutical and food products, needed reliable level measurement of their pellet storage silos, they turned to Flowline. The firm tools, injects, blow molds and silk screens thousands of bottles per hour for customers across the United States. Pellets of varying materials and colors are received, stored and vacuum transferred to the production floor. Plant operators complained that previous mechanical yo-yo level sensors, that drop and retract weights from the pellet surface, were unreliable, as their mechanical parts would break or jam. For this reason, Flowllne suggested our non-contact radar sensors that provide reliable, maintenance free pellet level measurement. The radar sensors provide reliable level data to the PLC, which monitors the silo inventories and alarms for replenishment. Flowline is reliable level measurement. |